Building a lean to shed can be a practical and cost-effective solution for additional storage or workspace on your property. Whether you need a place to store gardening tools, outdoor equipment, or create a workshop, a lean to shed can provide a functional and stylish solution. In this article, we will provide step-by-step instructions on how to build a lean to shed, along with tips and guidance to ensure a successful construction project.

Materials and Tools

Materials

- Pressure-treated lumber for framing, walls, and roof

- Plywood for walls, roof, and doors

- Asphalt shingles for roof covering

- Nails, screws, and hardware for fastening

- Roofing felt for moisture protection

- Doors and windows as needed

- Paint or stain for finishing

Tools

- Tape measure, level, and square for accurate measurements and alignments

- Circular saw for cutting lumber and plywood

- Nail gun or nailer for fastening nails quickly and efficiently

- Table saw for precise cuts

- Power miter saw for cutting angles and bevels

- Power sander for smoothing surfaces

- Ladder or scaffold for reaching higher areas of the shed

- Wheelbarrow or dolly for transporting materials

- Workbench or sawhorses for a stable work surface

- Safety equipment such as gloves, goggles, and ear protection

Step 1: Choose the Location

Choosing the right location for your lean to shed is essential for its functionality and longevity. Here are some key considerations:

Site Preparation

- Ensure the ground is level and stable. Clear any debris, rocks, or vegetation from the site.

- Check for underground utilities such as water, gas, or electrical lines. Avoid building over or near them.

- Consider the orientation of the shed. Choose a location that gets adequate sunlight, has good drainage, and is accessible.

- Check local building codes and regulations for setback requirements, permits, and other restrictions.

Foundation Options

There are several foundation options for a lean to shed, depending on your preference, budget, and local building codes. Here are some common options:

1. Concrete Slab

A concrete slab is a durable and stable option for a shed foundation. It requires excavation, forming, and pouring of concrete, which can be labor-intensive and costly. However, a concrete slab provides a solid and level base for the shed and helps to prevent moisture and pest infiltration.

2. Gravel Pad

A gravel pad is a less expensive and easier option for a shed foundation. It involves leveling the ground, spreading a layer of gravel, and compacting it. Gravel provides good drainage and stability, but may not be as durable as a concrete slab. However, it can be a suitable option for smaller sheds or temporary structures.

3. Pressure-Treated Wood Posts

Pressure-treated wood posts can be used as a foundation for a lean to shed. They are driven into the ground and provide a stable base for the shed. This option is cost-effective and relatively easy to install, but may not be as durable as a concrete slab or gravel pad. It is important to use pressure-treated wood to prevent rot and decay.

Step 2: Gather Materials and Tools

Once you have chosen the location and determined the type of foundation for your lean to shed, gather all the necessary materials and tools. Refer to the list of materials and tools mentioned earlier in this article. Make sure you have all the required items before starting the construction process to ensure smooth progress.

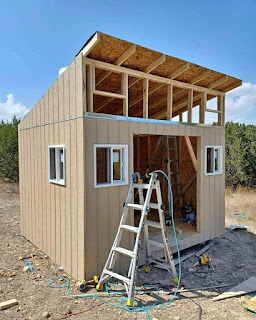

Step 3: Construct the Frame

The frame is the backbone of your lean to shed and provides the structure and stability for the entire shed. Follow these steps to construct the frame:

1. Measure and Cut Lumber

Measure and cut the pressure-treated lumber for the frame according to the dimensions of your shed. Use a tape measure, level, and square to ensure accurate measurements and cuts.

2. Assemble the Wall Frames

Assemble the wall frames on the foundation, using nails or screws to fasten the lumber together. Use a level to ensure the walls are plumb and square. Install the wall frames according to your shed's design, leaving openings for doors and windows as needed.

3. Install the Roof Rafters

Install the roof rafters on top of the wall frames, following the design of your shed. Use a level to ensure the rafters are level and aligned properly. Fasten the rafters to the wall frames using nails or screws.

4. Install the Plywood Sheathing

Install plywood sheathing on the walls and roof of the shed, using nails or screws to fasten it securely. Cut openings for doors and windows as needed. Make sure the sheathing is flush with the edges of the frame and aligned properly.

5. Install Roofing Material

Install asphalt shingles or other roofing material on the roof of the shed, following the manufacturer's instructions. Make sure the roofing material is properly aligned and fastened to provide adequate protection against weather elements.

6. Install Doors and Windows

Install doors and windows on the shed, following the manufacturer's instructions. Make sure they are properly aligned, level, and securely fastened. Install any additional hardware or accessories as needed.

Step 4: Finish and Customize Your Shed

Once the frame, walls, roof, doors, and windows are installed, you can finish and customize your lean to shed according to your preferences. Here are some options:

1. Paint or Stain

Apply paint or stain to the exterior walls and doors of your shed to protect it from the elements and enhance its appearance. Choose a color that complements your property and personal style.

2. Interior Finish

Finish the interior of your shed with insulation, drywall, or other materials to create a comfortable and functional space. Add shelves, hooks, or other storage solutions to organize your tools, equipment, and other belongings.

3. Flooring

Add a flooring option that suits your needs and preferences, such as plywood, vinyl, or concrete. Consider adding a moisture barrier or insulation underneath for added protection and comfort.

4. Electrical and Lighting

If you plan to use your shed for various purposes, such as a workshop or storage, consider installing electrical outlets, lighting fixtures, and other electrical components. Hire a qualified electrician to ensure safety and compliance with local building codes.

5. Ventilation

Proper ventilation is important to prevent condensation, mold, and mildew growth inside your shed. Install vents, windows, or a ventilation system to promote air circulation and maintain a healthy environment.

6. Security

Add security measures, such as locks, alarms, or surveillance cameras, to protect your shed and its contents from theft or vandalism. Consider adding windows or skylights to allow natural light while maintaining security.

FAQs

Q: Can I build a lean to shed on my own?

A: Yes, building a lean to shed can be a DIY project if you have basic carpentry skills and the right tools. However, it is recommended to have some experience in construction or seek assistance from a knowledgeable friend or professional if you are not confident in your abilities.

Q: How long does it take to build a lean to shed?

A: The time it takes to build a lean to shed depends on various factors, such as the size of the shed, your level of experience, and the availability of materials and tools. On average, it may take a few days to a couple of weeks to complete the construction process.

Q: Do I need a building permit to construct a lean to shed?

A: Building permit requirements vary by location, so it is essential to check with your local building department or municipality to determine if a permit is required for your lean to shed. Obtaining the necessary permits ensures that your shed complies with local building codes and regulations.

Q: Can I customize the design and size of my lean to shed?

A: Yes, you can customize the design and size of your lean to shed to suit your specific needs and preferences. However, it is important to ensure that any modifications or alterations comply with local building codes and regulations.

Q: Can I use my lean to shed for other purposes besides storage?

A: Yes, a lean to shed can be used for various purposes, such as a workshop, hobby space, gardening shed, or even as a small living space. However, it is important to consider factors such as ventilation, insulation, electrical wiring, and other requirements depending on the intended use of the shed.

Conclusion

Building a lean to shed can be a rewarding DIY project that provides you with a functional and customizable storage solution. By following step-by-step instructions and using the right materials and tools, you can construct a lean to shed that meets your specific needs and complements your property. Remember to choose a suitable location, determine the type of foundation, construct the frame, and finish and customize your shed to create a durable and functional structure that enhances your outdoor space.

0 comments:

Post a Comment

Note: Only a member of this blog may post a comment.