Greetings fellow woodworking enthusiasts! If you're in need of a practical and stylish storage solution for your backyard, you've come to the right place. In this article, we'll be taking a closer look at 8x8 lean-to shed plans, providing you with authentic and friendly advice to help you embark on your woodworking journey with confidence.

Why Choose a Lean-to Shed?

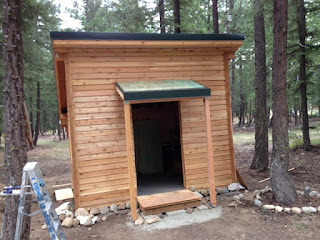

Before we delve into the details of building an 8x8 lean-to shed, let's first understand why this type of shed can be an excellent choice for your backyard. A lean-to shed, also known as a single slope shed, is a simple and cost-effective design that offers various advantages.

Firstly, a lean-to shed is space-efficient, as it can be built against an existing structure, such as a fence or a wall. This allows you to utilize the available space in your backyard more effectively, especially if you have limited space to work with. Additionally, a lean-to shed can provide easy access to your stored items, as it typically has a single door on the front for quick and convenient entry.

Moreover, a lean-to shed can be a great option if you're a beginner woodworker or have limited woodworking experience. Its simple design and construction make it an achievable project for those who are just starting out in woodworking or looking for a quick weekend DIY project.

Gathering Materials and Tools

Before you start building your 8x8 lean-to shed, you'll need to gather the necessary materials and tools. Here's a list of items you'll typically need:

- Pressure-treated lumber for the foundation, floor joists, and framing

- Plywood for the walls, roof, and floor

- Roofing materials, such as shingles or metal sheets

- Door and window (optional)

- Screws, nails, and other fasteners

- Measuring tape, level, hammer, circular saw, drill, and other basic woodworking tools

It's essential to choose high-quality materials that are suitable for outdoor use, as your shed will be exposed to the elements year-round. Pressure-treated lumber is an excellent choice for the foundation and framing, as it is resistant to rot and insect damage. Additionally, using plywood with a high-grade thickness will ensure the durability and stability of your shed.

Step-by-Step Building Process

Now let's dive into the step-by-step building process of an 8x8 lean-to shed:

Step 1: Prepare the Site

Start by clearing the area where you plan to build your shed. Make sure the ground is level and free from any debris or vegetation. Mark the location of the shed's four corners using stakes and string, and double-check the measurements to ensure that the corners are square.

Step 2: Build the Foundation

The foundation is a critical part of your shed, as it provides stability and prevents moisture from seeping into the structure. There are several options for the foundation of your lean-to shed, including a concrete slab, treated wood skids, or concrete blocks.

If you choose to build a concrete slab, you'll need to dig and level the area, pour a gravel base, and then pour the concrete. For treated wood skids, you will need to place pressure-treated lumber beams on the ground, leveled and spaced according to your shed's dimensions. Concrete blocks can also be used as a simple and cost-effective foundation option, where you'll need to level the blocks and place them at the corners and along the sides of the shed.

Step 3: Construct the Floor

Once the foundation is in place, you can start building the floor of your 8x8 lean-to shed. Start by laying pressure-treated lumber joists on top of the foundation, spaced evenly and attached with screws or nails. Then, cover the joists with plywood, leaving a small gap between the panels for expansion. Nail or screw the plywood to the joists, ensuring it is flush with the edges.

Step 4: Build the Walls

Next, it's time to construct the walls of your lean-to shed. Measure and cut the wall studs from pressure-treated lumber according to your shed's height, leaving space for the door and window if desired. Attach the studs to the floor joists and each other using screws or nails, ensuring they are plumb and square.

Once the wall frames are built, you can attach plywood sheets to them to form the walls. Make sure the plywood is flush with the edges of the wall frames and fasten them securely with screws or nails. You can also add a window or a door, following the manufacturer's instructions for installation.

Step 5: Install the Roof

The next step is to install the roof on your 8x8 lean-to shed. Start by attaching pressure-treated lumber rafters to the top of the wall frames, ensuring they are evenly spaced and level. Then, cover the rafters with plywood, leaving a small overhang on the front and back for water runoff.

Once the plywood is in place, you can install the roofing material of your choice, such as shingles or metal sheets. Follow the manufacturer's instructions for installation, making sure the roof is properly sealed to prevent leaks.

Step 6: Finishing Touches

With the main structure of your lean-to shed complete, you can add some finishing touches to enhance its functionality and aesthetics. You can install shelves, hooks, or pegboards on the walls to create storage space for your tools and equipment. You can also paint or stain the shed to protect it from the elements and give it a polished look.

Conclusion

Congratulations! You've successfully built your own 8x8 lean-to shed. With its simple design, space-efficient layout, and easy construction process, a lean-to shed can be a practical and stylish addition to your backyard, providing you with a functional and attractive storage solution for your woodworking projects, gardening tools, or outdoor gear.

Remember to always follow safety guidelines and use high-quality materials when building your shed. Take your time with each step, measuring and leveling carefully to ensure a sturdy and stable structure. Don't hesitate to seek help or advice from experienced woodworkers if needed.

We hope this article has provided you with authentic and friendly guidance on building an 8x8 lean-to shed. Happy woodworking, and enjoy your newly built shed!

0 comments:

Post a Comment

Note: Only a member of this blog may post a comment.