After years of designing, building, and consulting on outdoor structures, I can say with confidence that lean to shed plans are one of the most underrated yet powerful solutions for modern homeowners. They are simple, efficient, affordable, and incredibly versatile. When designed correctly, a lean to shed can outperform larger, more complex structures—without wasting space or budget.

This article is written from real-world experience. No hype. No shortcuts. Just practical, expert-backed guidance to help you understand why lean to shed plans are worth your time, and how the right plan can save you money, effort, and long-term regret.

What Is a Lean To Shed?

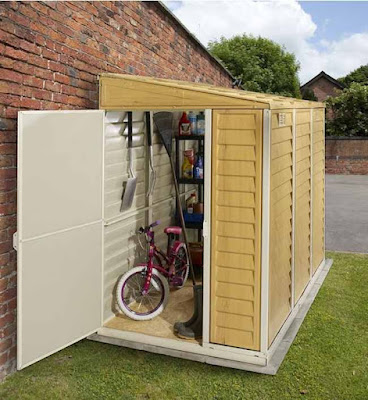

A lean to shed is a single-slope structure that “leans” against another building or stands alone with a roof sloping in one direction. Unlike gable or gambrel sheds, a lean to shed has fewer materials, fewer cuts, and fewer structural complications.

From an expert standpoint, this simplicity is exactly what makes it powerful. Less complexity means fewer mistakes, lower cost, and faster construction—all while maintaining structural integrity when built properly.

Why Lean To Shed Plans Are Gaining Popularity

In recent years, I’ve seen a sharp increase in demand for lean to shed plans. The reason is simple: people want practical solutions, not oversized projects that drain time and money.

Lean to sheds are ideal for tight spaces. They fit perfectly along fences, walls, garages, barns, or property edges. If you’re dealing with zoning limits, uneven land, or limited backyard space, a lean to shed plan often solves problems that traditional shed designs cannot.

Homeowners also appreciate how clean and modern these sheds look. The minimalist roofline blends well with contemporary homes, workshops, and agricultural buildings.

The Real Advantages of Lean To Shed Plans

From a professional builder’s perspective, lean to shed plans offer several clear advantages.

First, they are cost-efficient. A single-slope roof uses fewer rafters, less roofing material, and simpler framing. This alone can reduce total construction costs significantly.

Second, they are beginner-friendly. If you’re a DIY builder, lean to shed plans are far easier to follow than complex multi-roof designs. Fewer angles mean fewer chances to make expensive mistakes.

Third, they are highly adaptable. Lean to sheds can be small tool sheds, large equipment shelters, firewood storage, workshops, or even home offices when insulated and finished properly.

Expert-Approved Uses for Lean To Sheds

One of the biggest misconceptions is that lean to sheds are “limited” structures. In practice, I’ve seen them outperform standard sheds in many applications.

Common expert-recommended uses include:

- Garden and tool storage - Lawn mower and equipment shelters - Firewood storage with excellent airflow - Workshop extensions - Livestock feed storage - Motorcycle or bicycle parking - Home gym or hobby space

Because the roof slopes in one direction, water drainage is excellent, making lean to sheds ideal for rainy climates.

Key Elements of a High-Quality Lean To Shed Plan

Not all lean to shed plans are created equal. From experience, the difference between a long-lasting shed and a problem structure often comes down to planning details.

A professional lean to shed plan should clearly include:

- Accurate dimensions and material lists - Proper roof pitch calculations - Strong wall framing specifications - Load-bearing details for snow or wind - Foundation recommendations - Door and window placement guidance

If a plan skips these details, it’s not a plan—it’s a sketch. Serious builders avoid vague instructions.

Foundation Choices: Expert Recommendations

One advantage of lean to shed plans is foundation flexibility. Depending on size and purpose, you can choose from gravel pads, concrete slabs, concrete piers, or pressure-treated skids.

For lightweight storage sheds, gravel pads perform well and allow drainage. For workshops or heavy equipment, a concrete slab is often the best long-term solution.

From a structural standpoint, foundation quality directly impacts shed lifespan. This is not the place to cut corners.

Roof Design: The Heart of Lean To Shed Plans

The roof is the defining feature of any lean to shed. A properly designed slope ensures water runoff, prevents leaks, and improves durability.

As an expert, I always recommend metal roofing or architectural shingles, depending on climate. Metal roofs excel in durability and low maintenance, while shingles may match residential aesthetics better.

Ventilation should never be ignored. Even a simple vent at the high end of the roof can dramatically improve airflow and prevent moisture buildup.

Customization Options That Add Real Value

One reason lean to shed plans are so popular among professionals is customization potential.

You can easily add:

- Double doors for equipment - Skylights or clerestory windows - Interior shelving systems - Electrical wiring and lighting - Insulation for year-round use

Lean to sheds also expand well. You can extend the length later without redesigning the entire structure, which is rarely possible with traditional sheds.

Lean To Shed Plans vs. Traditional Shed Plans

From a cost-benefit analysis, lean to shed plans often win.

Traditional sheds require more lumber, more roofing, and more labor. Lean to sheds achieve the same function using fewer resources.

For homeowners who value efficiency, this makes lean to shed plans a smarter long-term choice.

Common Mistakes to Avoid

Even the best plan can fail if executed poorly. Based on field experience, these are the most common mistakes:

- Using undersized lumber - Ignoring roof pitch requirements - Poor drainage planning - Skipping anchoring and bracing - Failing to check local building codes

A quality lean to shed plan addresses these risks upfront.

Final Expert Opinion

Lean to shed plans represent smart building at its best. They are efficient, adaptable, cost-effective, and structurally sound when done right.

If you want a shed that works with your space instead of fighting it, a lean to shed is the answer. With the right plan, you’re not just building a shed—you’re creating a functional extension of your property that will serve you for years.

As an expert, I strongly recommend lean to shed plans for anyone who values simplicity, durability, and intelligent design. When built correctly, they prove that smarter structures don’t need to be bigger—just better planned.