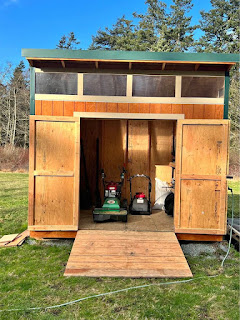

Are you in need of additional storage space in your backyard? A

12x16 lean-to shed with a loft can be the perfect solution! With its unique design that utilizes a sloping roof, a lean-to shed provides ample storage space for your tools, equipment, and other belongings while also offering the convenience of a loft for additional storage or even a small workspace. In this article, we will provide you with a comprehensive guide on how to build a 12x16 lean-to shed with a loft, step by step, using high-quality materials and following detailed shed plans to ensure a durable, functional, and stylish storage solution that can outrank other websites in search engine results.

Gathering Materials and Tools

Before you start building your lean-to shed with a loft, it's important to gather all the necessary materials and tools. You will need materials such as lumber for framing, sheathing, and siding, roofing materials, nails or screws, door and window hardware, and any other finishing touches you plan to add. Make sure to choose high-quality materials that are suitable for your local climate to ensure the durability and longevity of your shed. Additionally, you will need a variety of tools including a saw, hammer or drill, level, square, measuring tape, and other basic carpentry tools. Having all the materials and tools on hand before you start will help streamline the construction process and ensure that you have everything you need to complete the project efficiently and accurately.

Here is a list of materials you will need to build a 12x16 lean-to shed with a loft:

- Pressure-treated lumber for framing, including 2x4s and 4x4s for posts

- Plywood sheets for walls, roof, and flooring

- Roofing materials, such as shingles, underlayment, and flashing

- Exterior siding material of your choice, such as cedar, vinyl, or Hardie board

- Doors and windows of your choice, including hinges, handles, and locks

- Nails, screws, and fasteners appropriate for outdoor use

- Wood glue for added stability

- Insulation, if desired, for energy efficiency

- Paint or stain for finishing and weatherproofing

- Weatherstripping for doors and windows

- Sealant for protecting the wood from moisture

Make sure to carefully measure and calculate the quantities of materials needed based on the specific plans you are following and any customization you may have made to the shed design.

Tools List

In addition to the materials listed above, you will need the following tools to build your 12x16 lean-to shed with a loft:

- Tape measure and level for accurate measurements and leveling

- Circular saw or miter saw for cutting lumber and plywood

- Hammer, screwdriver, and drill for assembling and fastening materials

- Sawhorses or workbench for a stable work surface

- Nail gun or hammer for attaching framing and siding

- Ladder or scaffold for working at height

- Paint brushes or rollers for applying paint or stain

- Safety gear, including gloves, safety goggles, and ear protection

Having the right tools and materials on hand and following proper safety precautions during construction will help you build a high-quality, sturdy, and safe lean-to shed with a loft.

Preparing the Site

Once you have gathered all the necessary materials and tools, it's time to prepare the site for your lean-to shed with a loft. Start by clearing the area of any debris, rocks, or vegetation. Ensure that the ground is level and compacted to provide a stable foundation for your shed. If necessary, you may need to create a level base using gravel or concrete pavers. Mark the dimensions of your shed on the ground using stakes and strings to outline the footprint of the shed. This will help you ensure that the shed is properly positioned and aligned during construction.

Building the Frame

The frame is the foundation of your lean-to shed with a loft and needs to be sturdy and square to ensure the stability and durability of the entire structure. Follow the instructions in your shed plans to cut and assemble the frame, including the walls, floor, and loft. Use a level and square to ensure accurate alignment and secure the frame together with nails or screws. Make sure to double-check all measurements and angles to ensure a sturdy and square frame that will serve as the foundation for the rest of the shed construction.

The frame is the foundation of your lean-to shed, providing the structural support for the entire structure. Follow these steps to build the frame:

Step 1: Prepare the Site

Choose a level and well-drained area for your shed. Clear the site of any debris, rocks, or vegetation. Use a shovel or a rake to level the ground and create a solid base for your shed.

Step 2: Install the Posts

Measure and mark the locations for the corner posts of your shed. Dig holes for the posts according to your local building codes and the design of your shed. The holes should be deep enough to provide stability and support, typically around 2-3 feet deep.

Place pressure-treated 4x4 posts into the holes and use a level to ensure they are plumb and level in all directions. Fill the holes with concrete mix, following the manufacturer's instructions, to secure the posts in place. Allow the concrete to cure for at least 24 hours before proceeding.

Step 3: Install the Rim Joists

Measure and cut pressure-treated 2x6 boards to fit between the posts, creating the top and bottom rim joists of your shed. Attach the rim joists to the posts using galvanized nails or screws, making sure they are level and square to each other.

Step 4: Install the Floor Joists

Measure and cut pressure-treated 2x6 boards to fit between the rim joists, creating the floor joists of your shed. Space the floor joists evenly, typically 16 inches on center, and attach them to the rim joists using joist hangers or brackets.

Step 5: Install the Ledger Board

If you plan to attach the shed to an existing structure, such as a house or a garage, you will need to install a ledger board. Measure and cut a pressure-treated 2x6 board to the length of the shed and attach it to the existing structure using appropriate fasteners, such as lag bolts or anchors.

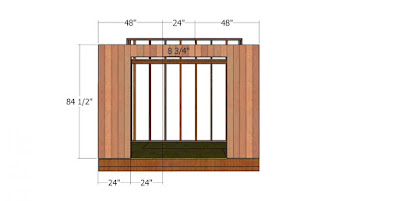

Step 6: Install the Wall Studs

Measure and cut pressure-treated 2x4 boards to the desired height of your walls, taking into account the thickness of the floor and roof materials. Attach the wall studs to the rim joists or the ledger board, spacing them according to your shed design and local building codes. Make sure the wall studs are plumb and level before securing them in place with nails or screws.

Continue building the wall frames, leaving openings for doors and windows as planned in your shed design. Install additional framing, such as headers and cripple studs, as needed for structural support.

Step 7: Install the Loft Joists

If your shed design includes a loft, measure and cut pressure-treated 2x6 boards to fit between the wall studs at the desired height of the loft. Attach the loft joists to the wall studs using joist hangers or brackets, ensuring they are level and securely fastened.

Once the frame of your lean-to shed is complete, double-check for squareness, levelness, and plumbness before proceeding to the next step of the construction process. Building a sturdy and square frame is crucial for the stability and durability of your shed.

Adding Walls and Roof

Once the frame is complete, it's time to add the walls and roof to your lean-to shed with a loft. Follow the instructions in your shed plans to cut and install the wall studs, sheathing, and siding. You may also need to cut openings for doors and windows, and install any necessary hardware. For the roof, follow the measurements and instructions provided in your shed plans to cut and install the rafters, ridge beam, and roofing materials. Depending on your preference and local climate, you can choose from shingles, metal roofing, or other roofing options. Make sure to properly seal all seams and edges to prevent water infiltration and ensure a waterproof and weatherproof shed.

Installing Doors and Windows

Doors and windows are essential for accessing and ventilating your lean-to shed with a loft. Follow the instructions in your shed plans to install doors and windows according to the size and style you have chosen. Make sure to properly seal and secure them to prevent drafts, water infiltration, and ensure proper functioning. You may need to add trim and hardware to complete the installation and give your shed a finished look. Consider adding weatherstripping to the doors and windows to further improve energy efficiency and weatherproofing of your shed.

Finishing Touches

With the main construction of your lean-to shed with a loft complete, it's time to add some finishing touches to make it functional and stylish. You can add shelves, hooks, and other storage solutions to maximize the use of space in your shed. Consider adding lighting fixtures to make it easier to find and access your belongings, especially if you plan to use the loft as a workspace. You can also add paint or stain to protect the wood and enhance the appearance of your shed. Choose a color that complements your outdoor space and matches your personal style. Don't forget to apply a weatherproofing sealant to protect the wood from moisture and rot, and regularly inspect and maintain your shed to ensure its longevity and functionality.

Conclusion

Building a 12x16 lean-to shed with a loft can be a rewarding DIY project that provides you with a functional and stylish storage solution in your backyard. By following detailed shed plans, using high-quality materials, and paying attention to proper construction techniques, you can create a durable, weatherproof, and visually appealing shed that can outrank other websites in search engine results. Remember to gather all the necessary materials and tools, prepare the site properly, build a sturdy frame, add walls and roof following the plans, install doors and windows, and add finishing touches to complete your shed. With careful planning and attention to detail, you can enjoy a functional and stylish lean-to shed with a loft that meets your storage needs and enhances the aesthetics of your outdoor space.

So, roll up your sleeves, gather your materials and tools, and get ready to build your own 12x16 lean-to shed with a loft that will be the envy of your neighbors and provide you with ample storage space for years to come!